Product Manufacturing Process

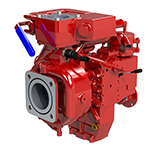

Godiva provides a world class product to a global market, these products are supported by a world class manufacturing process.

Quality control – inspection and test procedures to ISO9001:2015, 14001:2015 and CCC standards

Godiva has developed a supplier and vendor partnership where supplier performance is monitored, evaluated and graded through a series of key performance indicators. The successful partnership model is one we seek to use with all our suppliers.

Lean manufacturing principles and methodologies are deployed at the right time such as Value Stream Mapping, 5S’s, MUDA, TPM, QOS, Kaizen, Kan-ban, Poka Yoke and with a view to creating a culture of lessons learned, deploying problem solving techniques and KPI’s, thus ensuring the manufacturing of product is maintained at high levels of competency and meeting customer requirements.

Product manufacture is in dedicated cell stations by experienced and knowledgeable assemblers. Staff are encouraged to become multi-skilled across the range of Godiva pump builds, enabling the transfer of manpower to the in-demand product line with greater ease.