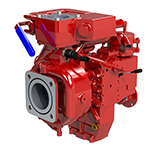

KP Pump – ideal for the small appliance

The KP pump is an innovative new pump that covers the lower end of the pumping range. With the demand for smaller more cost effective fire appliances, Godiva considered the user requirements and set to designing a new pump for the discharge flows up to 1500 l/min at 10 bar. This being a Godiva pump, there is a single pressure discharge the KP1_1510, and a multi-pressure option the KP2_1510. The multi-pressure version has inherited the unique Godiva design of two impellers on a single shaft, a design that always reduces space demands, and nowhere more significant than with the KP pump.

Key features and benefits of the KP pump –

|

FEATURE |

BENEFIT |

|

Small Size |

Allows more room for additional equipment |

|

Light weight |

Pump can be fitted to smaller chassis |

|

Output Options |

Single-pressure pump performance to EN1028 rated 1500 LPM @ 10 bar Multi-Pressure pump performance to EN1028 rated 1500 LPM @ 10 bar and 250 LPM @ 40 bar |

|

5 year maintenance interval |

Reduces downtime and maintenance costs |

|

Single Piston Primer |

Simple construction for low cost of ownership, with fewer parts |

|

Fail safe electric primer shutoff |

Ensures primer not activated at higher speeds, greatly increasing the life of the primer |

|

Easily removable primer seal assembly |

Seal assembly removed by two bolts so assembly can be maintained at a work bench |

|

Symmetrical design |

Identical plumbing can be used on engine and opposite engine rotation pumps |

|

Three gearbox orientations |

Left, right, and down orientations for installation flexibility |

|

Three volute orientations on single-pressure pump |

Left, right, and vertical orientations for plumbing flexibility |

|

Three gear ratios |

1.90:1, 2.33:1, 2.91:1 ratios to suit most engine and PTO applications |

|

Light alloy and gunmetal options |

To suit pumped water type |

Until now you had to choose between performance and size. With the KP series there is no compromise. Now you can select a single or a multi-pressure pump with one of the most compact footprints in the industry. In fact the KP single pressure pump is on average 40% smaller in cubic volume than the competition and the multi-pressure pump is on average 30% smaller in cubic volume than the comparable multi-pressure pumps. This frees up valuable space on the vehicle to carry more equipment or reduce the overall payload of the vehicle to reduce costs.

In addition size we have made the KP pump significantly lighter. In fact the KP single-pressure pump is on average 30% lighter and the KP multi-pressure pump is on average 25% lighter than the competition.

The size and weight advantage between the KP pump and the competition makes it ideally suited for today’s compact vehicle designs. It is now possible to install a high performance pump in a vehicle as small as 3.5 tonnes.

The KP pump is engineered symmetrical around the centreline. This makes the location for discharges for clockwise and counter-clockwise rotation pumps identical, greatly simplifying the installation time and costs.

In addition to being symmetrical the volute is offered in the standard, vertical orientation but can also be ordered with the discharge to the left or right (Single-pressure model only).

To reduce maintenance costs the piston primer is a true dry running design with no forced mechanical maintenance. An electronic clutch is included with the primer for fully automatic or manual priming. An electronic safety interlock is an integral part of the piston primer design ensuring it is not activated at high speeds. This interlock increases the life expectancy and reliability of the priming system which significantly reduce maintenance costs

The standard inclusion of a gearbox allows the KP pump to be installed in virtually every commercial chassis in the market. Even with the addition of the gearbox we are still lighter and smaller than the competition. In order to fit the various chassis’ the gearbox can be mounted in the down, left or right position. In addition there are three gearbox ratios available to suit most engine and PTO applications.

To reduce downtime and maintenance costs the gearbox design incorporates elements that mean the oil changes only once every 5 years, when installed and operated according with our O&M instructions.

The rising cost of maintenance was a major priority when designing the KP series.

- A sight tube is included so oil levels can be quickly assessed without disturbing plumbing

- The mechanical seal can be changed without removing the pump from the vehicle

- The primer was designed so that with the removal of two bolts the assembly containing the seals can be removed and maintained on a workbench instead of in the rear locker

- The primer was also designed as a single piston primer to have fewer parts

Contact Godiva to learn more about the KP pump range – Tel: +44 (0)1926 623600, godivacustomerservice@idexcorp.com.